The Transair Advantage

The Transair advantage avoids the problems encountered with galvanized steel pipe. Transair pipe is constructed in aluminum which prevents corrosion. The inner surface of aluminum pipe ensures good and constant quality clean air continuously. From the compressor to point of use, Transair pipework systems give higher longevity of equipment and avoid frequent changes of filter elements. For renovation projects, Transair pipework systems can be easily connected to copper or steel pipe. They offer higher performance and make it easy to extend an existing network.

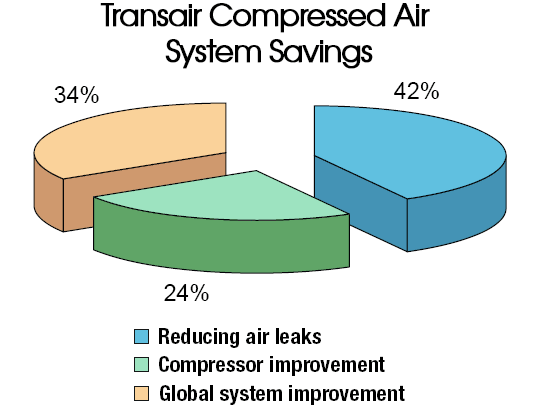

The inner surface of galvanized steel pipe gradually corrodes in contact with water. Corrosion causes the formation of oxide particles and cavities. Compressed air is polluted and damages equipment. Deposits accumulate and create roughness, reducing air flow and increasing pressure drops. Moreover corrosion is a source of air leaks: up to 30% of the volume of air may be wasted due to leaks with an old pipework system.

Qualicoat Certification is a guarantee of the quality of the Epoxy Powder Coating Finish applied to Transair aluminum pipe.

➤ Click here to learn more about Transair's Qualicoat Epoxy Powder Coating

➤ Click here to see Transair Certifications

Transair Advantages:

• Optimum efficiency

- absence of corrosion

- “full flow” design

- excellent sealing

• Reduced installation costs

- easy installation

- quick assembly

- immediate pressurization

• Adaptability

- modular design

- dismountable and reusable

- fast expansion

Your compressed air distribution piping is your means for transporting compressed air and represents your link between supply, storage, and demand. Furthermore, compressed air represents one of the largest opportunities for immediate energy savings. A properly designed Transair compressed air system typically saves a plant 20% to 50% of its electric bill, sometimes even up to 60% within 24 months. Labor accounts for only 20% of installation costs, compared to the 50-80% of such costs associated with traditional steel or black iron compressed air piping. While traditional products often corrode and degrade over time, Transair aluminum piping consistently provides clean, quality air though its leak-free, corrosion-resistant design, ensuring longevity of the equipment.

In recent years, aluminum-based compressed air piping systems have risen in popularity, particularly due to several factors:

• Modularity

• Quick Installation

• Aestheticism

Traditional Piping Systems Vs. Transair

The compressed air industry has long been dominated by traditional piping systems including steel, stainless steel, copper, plastic, and black iron. While these types are very familiar to the market, they present a number of disadvantages:• Labor intensive

• Installation can be dangerous from flames and fumes when welding

• Air leaks

Plastic

• Extremely dangerous due to over pressurization

• Expansion/dilatation

• Short system life expectancy

Steel

• Specialist tools required

• Experienced fitters only

• Corrosion susceptibility leads to internal surface roughness

• High-pressure drop/air leaks

Black Iron

• Very heavy and difficult to install

• Susceptible to corrosion and air leaks

• Experienced fitters only

• Difficult to modify

• Costly to repair

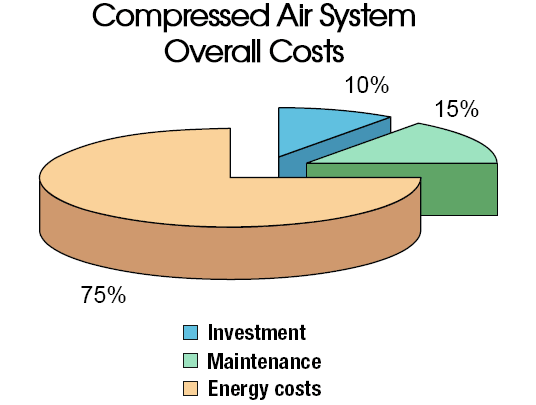

Compressed air represents 10% of industrial energy costs. Thus, optimizing and controlling its production and use is an opportunity to make immediate energy savings. After a ten-year period, the cost of energy consumed exceeds the initial cost of equipment and installation. Improving a pipework system gives potential cost savings of 34%.

Also Available from mdi

|

TransairAluminumPipe.com is owned and operated by mdi, Manufacturers Distributor, Inc. mdi is an Authorized Parker Transair Piping System Distributor. Click Here to view the mdi Line Sheet. |

Click For Larger View

Click For Larger View