Genuine Transair® Pipe and Fittings

With over 1,500,000 installations in the USA, Transair® is the unquestioned leader in compressed air systems. Transair® is the only Aluminum Pipe System that meets ASME certification and it's the only product with true push-to-connect fittings.

Transair®, the "original" modular compressed air system utilizing aluminum pipe and push-to-connect fittings, was launched in 1996. Since then, with more than 20 years experience, continual improvements have been made to meet the needs of compressed air, inert gas, vacuum networks and other industrial fluids.

Genuine Transair® is perfectly adapted to the constraints and needs of all industries and is recognized for its performance, from the compressor room to the point of use, in all industrial and automotive sectors.

Quality Certifications

Transair® tracks each production batch at every stage of its manufacturing process. All products are marked individually for an optimum follow-up (batch number and barcode on packaging). The origin of the products and the material certificates are available upon request. Transair® aluminium range conforms to ISO 8573: 2001 & 2010 Classes 1.1.1 certification.ISO 8573 certification establishes the different quality classes of compressed air for the 3 main components present in any compressed air system: dust, water and grease. Transair® aluminium range has been successfully tested to reach the highest expectation of this standard. A Transair® distribution network guarantees a constant quality of the conveyed fluids, from the production point to the point of use.

Benefits and Features of Genuine Transair® Pipe

• The quick connections eliminate the need to thread, solder or weld pipe• Labor accounts for only 20 percent of installation costs, but with steel or copper, labor accounts for 50 - 80% of the installation cost

(Click here to watch the "Transair Pipe Challenge" video)

• Transair uses a Double D-rings to seal fittings. The competition uses O-rings which may leak after time.

• Transair installs 4x faster and is 4x lighter

• Modular design, dismountable and reusable

• Recyclable components

• For superior performance, Transair uses the highest quality aluminum and stainless steel alloys to increase corrosion resistance

• Transair’s aluminum pipe system also significantly reduces plant energy costs by increasing efficiency, reducing pressure drops

• Guaranteed Leak Free for 10 Years*

• Exterior Qualicoat Epoxy Powder Coating (click here to learn more)

• Immediate Pressurization, no waiting

• Fast expansion, take it down and re-install at a new location

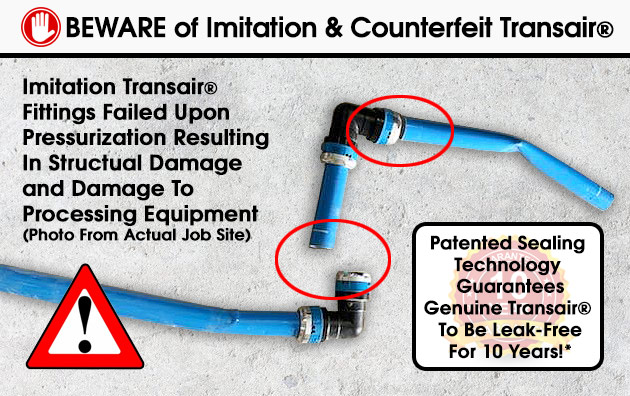

Beware of Imitation & Counterfeit Transair® Pipe

Beware of Imitation & Counterfeit Transair® Pipe and Fittings!! Transair® Pipe and Fittings have been imitated by several competitors, but never duplicated. Transair® was the first, is the best and is the only ground up pipe product made for inert gases such as compressed air.

*Parker Hannifin Corporation warrants its Transair®

products to be free of defects in material and

workmanship for a period of ten (10) years from

the date of purchase of the products.

*Parker Hannifin Corporation warrants its Transair®

products to be free of defects in material and

workmanship for a period of ten (10) years from

the date of purchase of the products.

Transair® Pipe, Connectors, and Valves:

Email this Page

Also Available from mdi

|

TransairAluminumPipe.com is owned and operated by mdi, Manufacturers Distributor, Inc. mdi is an Authorized Parker Transair Piping System Distributor. Click Here to view the mdi Line Sheet. |

Click Here to See Transair®

Click Here to See Transair® Transair Rigid Pipe

Transair Rigid Pipe Elbows

Elbows Tees

Tees Valves

Valves