Transair® Training

Installation Instructions, Videos, & Tips

Installation Instructions

Installation Guides with Videos• Pipe - 1/2"(16.5mm), 1"(25mm), & 1-1/2"(40mm) Installation Instructions w/ Video

• Pipe - 2"(50mm) and 2-1/2"(63mm) Installation Instructions w/ Video

• Pipe - 3"(76mm), 4"(101mm), & 6"(168mm) Installation Instructions w/ Video

• Pipe - 8"(220mm) Installation Instructions

• Quick Assembly Brackets - 1"(25mm) & 1-1/2"(40mm) Installation Instructions w/ Video

• Quick Assembly Brackets - 2"(50mm) & 2-1/2"(63mm) Installation Instructions w/ Video

• Quick Assembly Brackets - 3"(76mm), 4"(101mm), & 6"(168mm) Installation Instructions w/ Video

• Flexible Hose Connections - 1"(25mm) & 1-1/2"(40mm) Installation Instructions

• Flexible Hose Connections - 2"(50mm) & 2-1/2"(63mm) Installation Instructions

• Flexible Hose Connections - 3"(76mm), 4"(101mm), & 6"(168mm) Installation Instructions

• Automatic Safety Couplers

General

Prior to the installation of a Transair® compressed air

distribution system, the installer should ensure that the

installation area complies with any regulations applicable

to areas exposed to explosive hazards (in particular

the effect of static electricity in a silo area). Transair®

should be installed downstream of the compressed air

receiver, or after the dryer. Flexible Transair® hose can be

installed at the start of the system in order to eliminate

any sources of vibration and to facilitate maintenance

operations. When maintaining or modifying a Transair®

system, the relevant section should be vented prior

to the commencement of any work. Installers should

use only Transair® components and accessories, in

particular Transair® pipe clips and fixture clamps. The

technical properties of the Transair® components, as

described in the Transair catalog, must be respected.

Pressurizing the System

Once the Transair® installation has been installed and

prior to pressurizing, the installer should complete

all tests, inspections and compliance checks as

stated in any contract and according to sound

engineering practice and current local regulations.

Transair® Pipe and Hoses

Transair® pipe should be protected from mechanical impact,

particularly if exposed to collision with fork-lift trucks

or when sited in an environment with moving overhead

loads. Similarly, rotation of the pipe and pipe supports

should be avoided.Transair pipe must not be welded.

Flexible Transair hoses should be used in accordance

with the recommendations of the installation guidelines.

Expansion/Contraction

Expansion and contraction of the system should be

calculated prior to installation. The system designer

and installer should calculate the elongation or

retraction of each Transair line according to the

recommendations in this installation guide.

Component assembly

Transair® components are provided with assembly

instructions for their correct use - simply follow the

methods and recommendations stated in this document.

Transair® Installations - Situations to Avoid

■ Installation within a solid mass (concrete, foam, etc.)

■ The hanging of any external equipment to Transair pipe

■ The use of Transair for grounding, or as a support for electrical equipment

■ Exposure to chemicals that are incompatible with Transair components (please contact mdi for further details)

Sound engineering practice for the optimization of an air pipe system

■ When installing a Transair system, the work should be performed in accordance with good engineering practice.

■ Bends and bypasses represent sources of pressure drop. To avoid excessive pressure loss, use modular consoles to offset the network and to bypass obstacles. Keep in-line pipe diameter reductions to a minimum.

■ Maintain a consistent level of good quality air by use of adequate filtration at the compressor outlet.

■ The diameter of the pipe will influence pressure drop and the operation of point-of-use equipment. Select the diameter according to the required flow rate and acceptable pressure drop at the point of use.

■ Position drops should be as close as possible to the point of use.

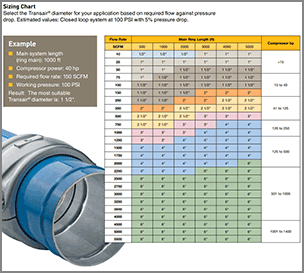

Transair® Pipe Size Selector

Select the Transair® pipe diameter for your application based on required flow against pressure drop.Estimated values: Closed loop system at 100 PSI with 5% pressure drop.

Quick Connection Technology

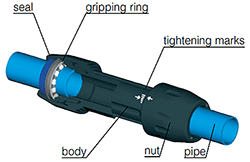

Transair’s innovative technology enables rapid and easy assembly with quick connection of components to the aluminum pipe. This technology takes into account the specific requirements of each diameter and provides the user with an optimum safety coefficient and easy connection.Ø 1/2" (16.5mm) – Ø 1" (25mm) – Ø 1 1/2" (40mm)

Pipe-to-pipe and male connectors in Ø 1/2", Ø 1" and Ø 1 1/2" can be immediately connected to Transair pipe – simply push the pipe into the connector up to the connection mark. The gripping ring of each fitting is then automatically secured and the connection is safe.

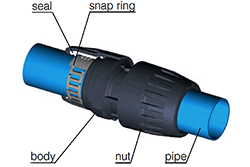

Ø 2" (50mm) – 2 1/2” (63mm)

Pipe-to-pipe and male connectors in Ø 2" and Ø 2 1/2" can be quickly connected to Transair aluminum pipe by means of a snap ring. This secures the connection between the nut and the pipe – tightening of the nuts secures the final assembly.

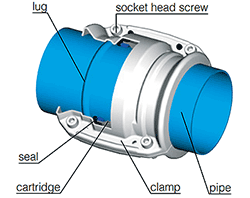

Ø 3" (76mm) – Ø 4" (101mm) – Ø 6" (168mm)

Pipe-to-pipe and male connectors in Ø 3", Ø 4" and Ø 6" can be quickly connected to Transair aluminum pipe. Position the pipes to be connected within a Transair cartridge and close/ tighten a Transair clamp.

Installation Training Certification

mdi offers it's customers "Contactless" Transair® Installation Training and Certification for all sizes of pipe and connectors. We are able to provide "Virtual Training" sessions via "Skype", "Zoom", or other popular video conferencing formats from our Transair® Training Center in Tampa, FL.Onsite installation training and certification is currently unavailable due to the COVID-19 pandemic.

Please call 727-835-0660 for availabilty and scheduling.

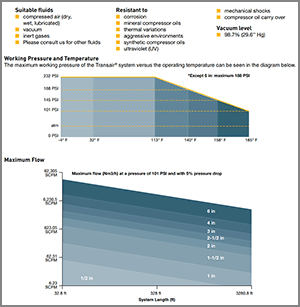

Transair® Technical Data

Transair® Technical Data Chart

Click for Larger View

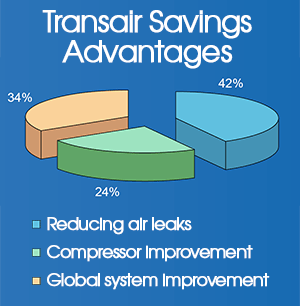

Transair® Equals Savings

Transair® Efficiency Equals Savings

Click for more information

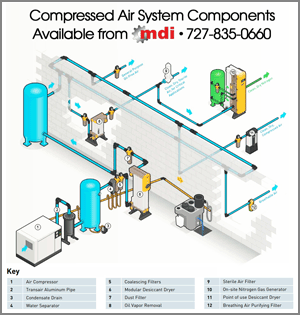

Compressed Air/Vacuum Systems

Not only does mdi offer Parker's complete line of Transair® Aluminum Pipe, Connectors, Valves, and Fixtures, but most components as well to complete your compressed air/vacuum system.mdi offers:

• Oil-less Air Compressors

• Vacuum Pumps

• Dessicant Dryers

• Refrigerated Dryers

• Membrane Dryers

• Nitrogen Gas Generators

• Hydrogen Gas Generators

• Water Seperators

• Coalescing Filters

• Breathing Air Purifying Filters

• Oil Vapor Removal Filters

• Particulate/Dust Filters

• Condensate Drains

• FRL's

• Compressed Air Hose Reels

• Pneumatic Tools

Compressed Air System Components

Click for Larger View

Call us TODAY at 727-835-0660 or

Toll Free at 800-761-4298

Request A Quote!

Also Available from mdi

|

TransairAluminumPipe.com is owned and operated by mdi, Manufacturers Distributor, Inc. mdi is an Authorized Parker Transair Piping System Distributor. Click Here to view the mdi Line Sheet. |

Transair® Sizing Chart - Click to View

Transair® Sizing Chart - Click to View